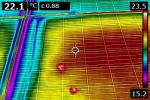

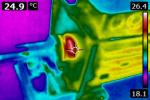

Infrared thermography is a non-destructive analysis technique based on infrared image acquisition using a thermal imaging camera. There are two ways to apply thermography: remote sensing thermography and contact thermography. Remote sensing thermography is mainly used in construction and in the analysis of electrical and mechanical systems, while contact thermography is based on the use of liquid crystal detectors and is mainly used in the medical field. GI srl performs thermographic surveys of systems and electrical panels, as well as motors and rotating machines in general (pumps, compressors, turbines)

Infrared thermography is a non-destructive analysis technique based on infrared image acquisition using a thermal imaging camera. There are two ways to apply thermography: remote sensing thermography and contact thermography. Remote sensing thermography is mainly used in construction and in the analysis of electrical and mechanical systems, while contact thermography is based on the use of liquid crystal detectors and is mainly used in the medical field. GI srl performs thermographic surveys of systems and electrical panels, as well as motors and rotating machines in general (pumps, compressors, turbines)The term thermography refers to the two-dimensional display of the radiation measurement. Through the use of the thermal imaging camera, non-destructive and non-intrusive controls are performed. Thermal imaging cameras detect radiation in the infrared range of the electromagnetic spectrum and perform measurements correlated with the emission of these radiations.

This instrument is able to detect the temperatures of the analyzed bodies by measuring the intensity of infrared radiation emitted by the body under examination. All objects at a temperature above absolute zero emit radiation in the infrared range. The thermography allows to visualize absolute values and temperature variations of the objects, independently from their illumination in the visible field.

A predictive analysis can be performed on electrical panels, motors and users, in order to avoid sudden failures during operation and to program maintenance correctly.

Infrared thermography is particularly suitable for the analysis of functioning, together with the vibrational analysis, because it allows to perform the checks without having to stop the user or the plant.